BIM Level 2 is now a standard on the majority of projects in the UK. VTA knows how best to implement BIM and keeps up with up to date with regulations and technologies. VTA integrates 3D models with data and databases containing detailed information, which our team is fully conversant in the requirements. Our models are precise and enable our clients to integrate with Trimble laser machine to auto-locate bracket fixing points. We also carry out point cloud laser surveys which allow us to process data with all survey information from remote sites in order to ensure the most optimal outcome is achieved.

VTA has worked for over a decade, managing data associated with the graphical models for building services, and has linked the two to allow data drops and schedules. The increasing use of BIM software has made the management of data more prescriptive, by deploying software such as Autodesk Construction Cloud, Revit, Fab MEP, Navisworks, and Recap along with plugins such as MagiCAD and DiRoots we achieve optimal performance of data management within the graphical model.

How we can assist your BIM project -

Model Validation – Detail report on buildability of the design with regards to M&E industry standards such as DW144 and EN 1366, access, maintenance, and spatial fit of services, and potential architectural and structural implication.

Model QA – Extensive review of model, schematics, and drawings, highlighting any inconsistencies between information.

Model Federation – Collating and management of trade models.

Clash Management – Identification of clashes between trades/disciplines, provide resolutions and assign ownership.

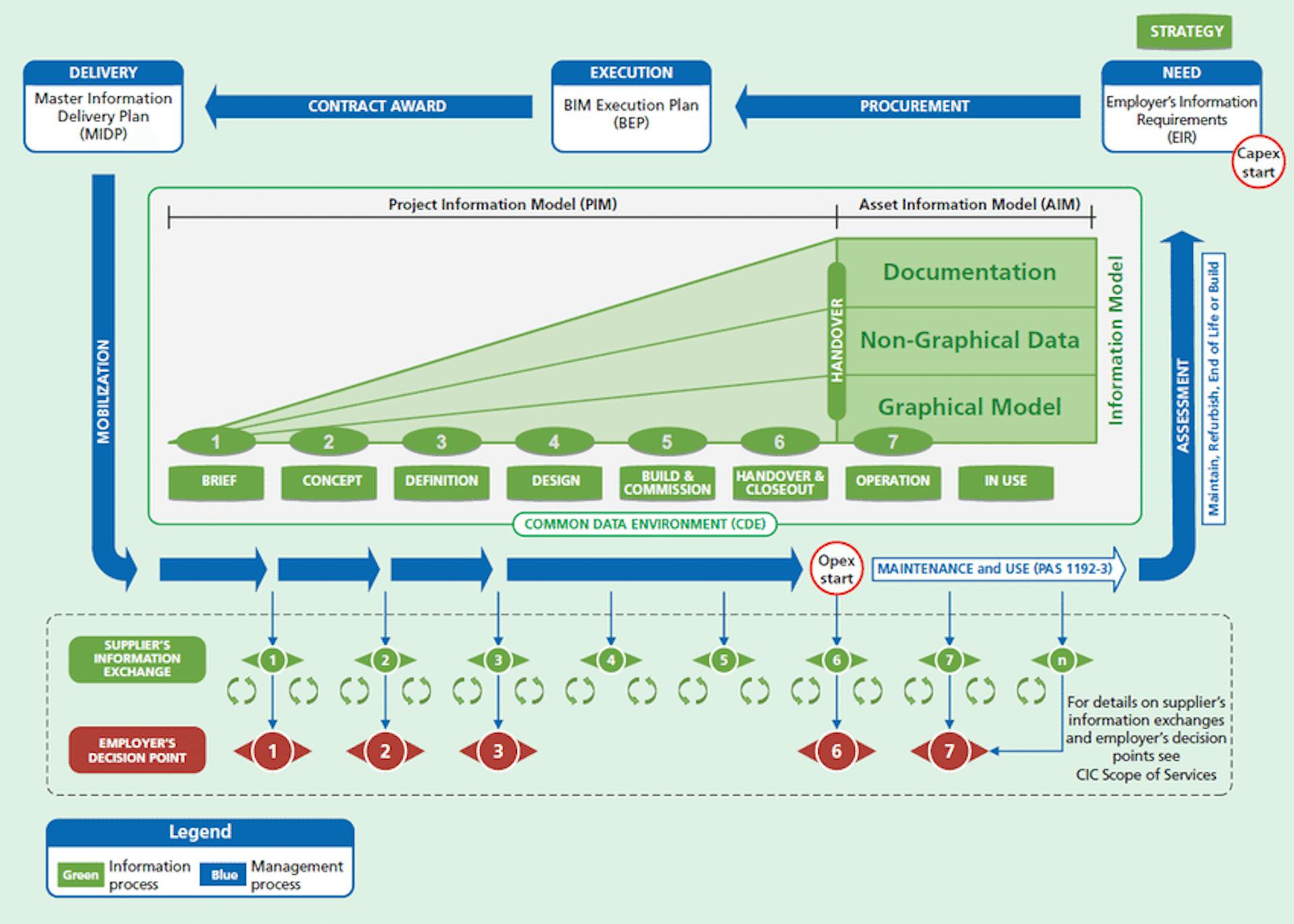

Asset Data Entry – Population of asset data within model elements complying with COBie or project BIM Execution Plan (BEP) requirements.

QR Code labels – Generation of QR code labels for asset management.

Asset Tagging -

It is common practice to assign an identifier or "brass tag" to a corporate asset. An asset tag is applied to a published asset or an imported model/assembly after it has been placed into a 3D factory layout. You assign a tag from the Asset Tag fields in the Factory Properties browser. Once defined, you can view the tag by hovering the cursor over the asset in a layout. Both asset tags and descriptors can contain multiple lines of alphanumeric text. The Search command helps you locate all assets or placed components with specific asset tags or descriptor character strings.

QR Codes -

Simply scan the QR tag using the camera on your smartphone or tablet, and you can start tracking and managing your assets instantly. When your asset tracking software incorporates asset tags, all it takes is a simple scan of the QR, and the asset's last known location will update, as well as the user who scanned it.

COBie -

COBie (Construction Operations Building Information Exchange) is an international standard that enables the transfer of building data. This data is transferred from design to construction and operations in a collaborative and clear format.

In order to improve the measurement and management of assets, it is recommended that clients request that specific information be delivered by the supply chain. The specified information set, called COBie, delivers consistent and structured asset information useful to the owner-operator for post-occupancy decision-making.

Using technical terms COBie is a ‘data schema’ that may be kept in a spreadsheet or, more effectively, in a database and can organise all data in a way that is compatible with all other data structures using this format.

COBie does not increase the need for information, it simply structures it in a more accessible format, so that it is easier to use and re-purpose. The format is intended to be easy to manage by any organisation, irrespective of size and IT capability. Its simplicity means that all tiers of the supply chain should be able to contribute to the data set, even if just by entering it directly into the spreadsheet. The format also 'insulates' the client from unnecessary complexity, technology changes, interoperability problems and proprietary software issues.

VTA can manage your data requirements on a project and achieve your required end result. Liaising with Facilities Maintenance specialists on a project (if available), VTA will identify the data required, integrate it with the graphical model such as QR codes, and achieve intermediate and final data drops to meet clients and stakeholders requirements.